Developed in 2020-2021, diameter Ø8 mm, bending angle ±60˚, consists of 5 separate parts.

In minimally invasive surgery, small incision sizes limit the manoeuvrability of surgical instruments. The number of degrees of freedom (DOF) of the instrument shaft can be increased by making the instrument tip steerable. Such instruments are controlled by the surgeon on the side of the handle. Steerable instruments offer many advantages in terms of DOF and functionality, however they have high mechanical complexity, and the steerable shaft can be difficult to operate for the surgeon.

Additive manufacturing (AM) can aid in the development of these instruments by reducing the mechanical complexity in the form of minimal assembly designs. The freedom of complexity offered by AM allows parts to be merged together into larger, more complex parts, that can be 3D printed in a single step. In addition, AM allows the production of one-off, personalized designs.

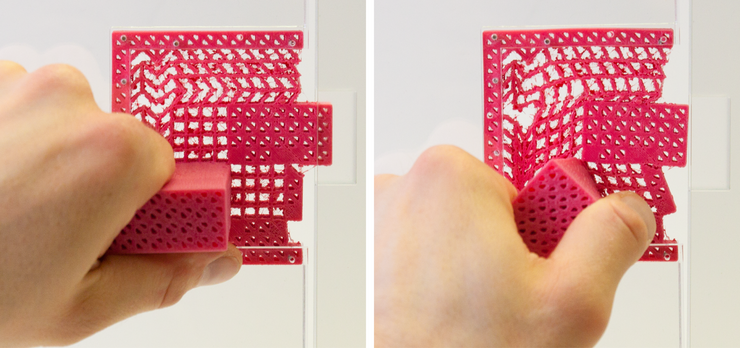

The 3D-GriP is a 3D printed steerable instrument that consists of only 5 separate parts. The handle part is designed based on ergonomic principles for handheld instruments, and can be adjusted to the size of the surgeon’s hands for a perfect fit. The joystick steers the instrument and works with a passive lock, which is automatically engaged when no pressure is applied. The grasper can be closed with the trigger, designed with two perpendicular flexures, which can be operated by one or two fingers, as the surgeon prefers.